- Best Practices ●

- COVID-19 ●

- Industry Trends ●

- Partners ●

- Product ●

Simplify Quality Control Processes with QR Codes

As a manufacturer, you’re under constant pressure to improve quality, traceability, and compliance while keeping operations efficient. Manual data entry and outdated systems often lead to errors, delays, and higher costs across manufacturing processes. When teams use QR Codes, they can streamline every step of quality control. A simple scan gives instant access to inspection checklists, batch details, compliance documentation, and real-time production updates.

Bitly helps manufacturers automate and optimize these workflows with enterprise-grade tools like Dynamic QR Codes, an analytics dashboard, and secure SOC-2 compliant infrastructure. By implementing QR Codes across the supply chain, manufacturers can improve quality assurance, strengthen traceability, and maintain compliance at scale without slowing down operations. This article examines how.

Note: The brands and examples discussed below were found during our online research for this article.

-

Table of contents

- Why QR Codes are transforming quality control

- Challenges with traditional quality control processes

- How QR Codes simplify quality control workflows

- Top use cases of QR Codes in manufacturing quality control

- Batch and ingredient tracking

- Compliance and audit readiness

- Equipment and maintenance QA

- Allergen and expiration tracking

- Customer-facing transparency

- Best practices for implementing QR Codes in quality control

- How Bitly supports quality control at scale

- Future-proof your quality control processes with QR Codes

Why QR Codes are transforming quality control

Manufacturers adopt QR Codes to speed up quality control, reduce errors, and gain access to real-time data. By scanning a code, teams can instantly view inspection results, update batch records, or verify compliance data within connected dashboards. This level of traceability strengthens every stage of the supply chain and reduces inefficiencies caused by manual workflows.

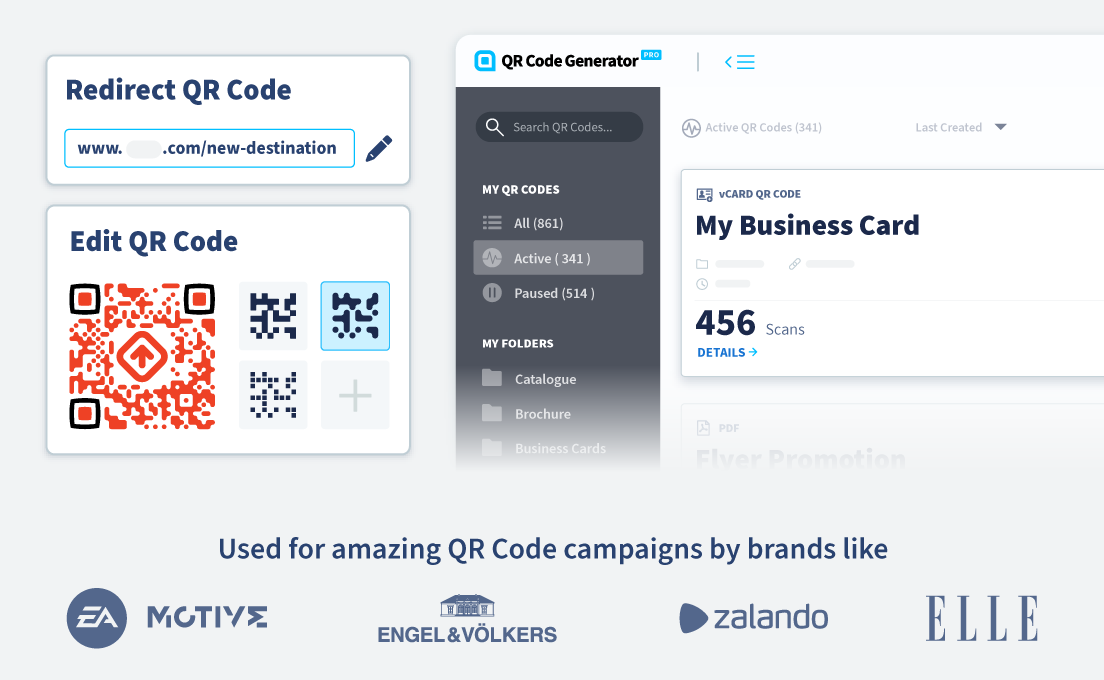

There’s really no comparison with traditional barcodes; QR Codes store more data and allow omnidirectional scanning, which makes them far faster and more reliable in dynamic production environments. Dynamic QR Codes add even more flexibility, letting your team edit destination URL data whenever required, without reprinting a single code.

Bitly’s enterprise-ready QR Code generator offers your team scalable, secure, and trackable solutions that integrate easily with existing systems. As Industry 4.0 continues to evolve, QR Codes have become the bridge between physical items and digital systems that enable smarter, compliance-focused manufacturing.

Challenges with traditional quality control processes

Manual data entry, paper checklists, and siloed workflows slow production. They also vastly increase the risk of costly errors, with some research showing that manual entry introduces a serious 1% error rate. When inspection data and serial numbers live in disconnected systems, teams lose visibility into quality issues, and traceability gaps make it harder to respond quickly to recall requirements or regulatory audits. Production downtime often follows because teams can’t access real-time updates or verify information fast enough.

QR Codes help eliminate these problems by connecting quality control steps in one streamlined process. They link directly to inspection logs, batch records, and dashboards that teams can access with a quick scan on any smartphone. This functionality means manufacturers can modernize without investing in expensive hardware, as employees already have the mobile devices they need to access QR Codes for quality assurance.

How QR Codes simplify quality control workflows

QR Codes for manufacturing can connect every part of the quality control process. With the correct setup, teams can scan a code to access inspection logs, maintenance schedules, inventory management consoles, or safety protocols. This real-time access removes guesswork and ensures everyone works with accurate data.

Automation through QR Codes reduces manual errors, accelerates inspections, and minimizes downtime across manufacturing processes. When integrated with ERP or inventory systems, QR Codes create seamless data flow that improves traceability and visibility across all production stages. By using Bitly’s QR Code generator, manufacturers can automate workflows, centralize documentation, and streamline reporting.

Top use cases of QR Codes in manufacturing quality control

Manufacturers across industries now use QR Codes to automate data collection, improve traceability, and strengthen quality assurance. By linking real-time data to every product, batch, or machine, they gain complete visibility from production to inspection. Top use cases include:

Batch and ingredient tracking

QR Codes give real-time visibility across the supply chain from raw materials to finished goods. Teams can track batch codes instantly, access inspection data, and speed up recall management when needed.

Compliance and audit readiness

QR Codes can link directly to audit trails, certifications, and regulatory checklists. Industries like aerospace, pharmaceuticals, and food manufacturing rely on these connections to meet strict regulatory standards. Bitly SOC-2 compliance ensures data integrity and enterprise-level security for all linked documentation.

Equipment and maintenance QA

Placing QR Codes on machinery connects teams to maintenance histories, repair logs, and safety procedures. Enforcing regular scanning practices can help teams reduce downtime, follow maintenance schedules, and improve operational consistency.

Allergen and expiration tracking

QR Codes can provide quick access to allergen information and expiration data for products like food, cosmetics, or pharmaceuticals. For example, Nestlé uses QR Codes for product information and allergen transparency, improving safety for consumers and confidence for inspectors.

Customer-facing transparency

Many manufacturers use QR Codes for digital product quality passports or ingredient disclosures to build brand trust and meet quality control standards. QR Codes in supply chain management can make it simple to let your customers see every step your product takes from your facility to their hands.

Best practices for implementing QR Codes in quality control

To get the most from QR Codes in quality control, manufacturers should focus on scalability, accuracy, and ease of use. Dynamic QR Codes provide flexibility because teams can update the URLs of linked content without reprinting. This is ideal for real-time updates to inspection logs, certifications, or maintenance data, especially if you use UTM tracking as part of your analytics schema.

Always place QR Codes on flat, visible surfaces and test them in real-world conditions to ensure consistent scannability. Integrating QR Codes with existing ERP or quality control systems prevents data silos and keeps workflows streamlined. Bitly Analytics can reveal where bottlenecks occur, helping teams optimize production processes and improve traceability.

Bitly’s bulk generation tools and API integrations simplify implementation at scale, allowing manufacturers to automate and track thousands of codes with precision. There are also dozens of pre-built integrations in the Bitly Marketplace designed to get connections with your existing tech stack up and running fast.

How Bitly supports quality control at scale

Bitly helps manufacturers centralize QR Code creation, editing, and management in one secure platform. Teams can generate QR Codes for every batch, checklist, or maintenance process, then track performance across facilities from a single dashboard.

With Bitly Analytics, manufacturers can monitor scan activity in real time, including location (city/country) and device type data. These insights can help identify inefficiencies, measure process adoption, and optimize workflows across complex global manufacturing environments.

Our SOC-2 compliance ensures enterprise-grade data protection, making Bitly a reliable solution for industries with strict regulatory requirements. More than a QR Code generator, Bitly acts as a trusted partner in manufacturing transformation by improving traceability, automation, and quality assurance at every stage of production.

Future-proof your quality control processes with QR Codes

QR Codes simplify quality control by improving efficiency, strengthening traceability, and ensuring compliance across manufacturing processes. A single scan can connect teams to inspection logs, certifications, and real-time updates, making operations faster and more transparent.

Bitly delivers an enterprise-ready, SOC-2 compliant solution that scales with your production needs. Our platform unites Dynamic QR Codes, analytics, and automation to help manufacturers manage quality control at scale while protecting data and maintaining compliance. As Industry 4.0 advances, QR Codes serve as both a practical upgrade and a long-term strategy for connected, data-driven manufacturing.

Are you ready to start building a smarter quality control process today? Log in now and learn more about how Bitly can help your enterprise secure the future it deserves.

Add custom colors, logos and frames.

Add custom colors, logos and frames.