- Best Practices ●

- COVID-19 ●

- Industry Trends ●

- Partners ●

- Product ●

RFID Tags vs QR Codes: Pros, Cons, and Top Use Cases

Businesses everywhere are rethinking how they track assets and connect with customers. You might be upgrading a warehouse tracking system or looking for new ways to bridge the physical and digital worlds. The technology you choose determines your operational speed and your budget. The biggest debate often centers on RFID tags vs QR Codes.

Both technologies enable digital identification, but they function in very different ways. Choosing the right one requires a clear look at your infrastructure, your budget, and your specific goals. This guide breaks down the key differences to help you decide which tool fits your business needs.

Note: The brands and examples discussed below were found during our online research for this article.

What are RFID tags?

Radio Frequency Identification (RFID) is a wireless technology that uses radio waves to identify and track objects. An RFID system consists of three core components: a scanning antenna, a transceiver, and a transponder (the tag itself), as well as a tracking database.

When the scanning antenna and transceiver combine, they form an RFID reader or interrogator. This device sends out a signal that activates the tag. The tag then sends data back to the reader, which records it in the database.

We generally categorize RFID tags into two types based on their power source:

- Active RFID tags: These tags have their own internal power source (usually a battery). This allows them to broadcast a signal over longer distances, sometimes up to 150 meters. Companies often use them for tracking large assets like cargo containers or vehicles.

- Passive RFID tags: These tags do not have an internal power source. They rely entirely on the energy transmitted by the RFID reader to power the internal microchip and send a signal back. They are smaller and cheaper than active tags but have a shorter read range.

How do RFID tags work?

The process begins when an RFID reader transmits an encoded radio signal. This signal “wakes up” the tag. The tag responds by transmitting its unique identification information back to the reader.

A major advantage here is that RFID technology does not require direct line of sight. You do not need to point a scanner directly at the label. As long as the tag is within the range of the radio waves, the reader can capture the data. This capability allows for automation in bulk scanning.

For example, a reader on a conveyor belt can scan hundreds of items in seconds as they pass through.

However, electromagnetic fields from metal or liquid can sometimes interfere with readability. You also need specific hardware to make this system work.

- Pros:

- Can work at a considerable range.

- No line of sight required.

- Can work at a considerable range.

- Cons:

- Subject to interference.

- Requires specialized hardware.

- Subject to interference.

RFID tag use cases

RFID tags excel in environments where speed and volume matter most.

- Supply chain and logistics: Companies use RFID to track shipments moving through distribution centers without manual scanning.

- Asset tracking: Large enterprises use active RFID tags to monitor expensive equipment across sprawling facilities.

- Manufacturing: Factories use RFID tags to track parts through the assembly line to ensure quality control.

- Access control: Most employee ID badges and hotel room keys use RFID technology or NFC (a subset of RFID) to unlock doors.

What are QR Codes?

Quick response codes (QR Codes) are two-dimensional matrix barcodes. Unlike standard barcodes that only store data horizontally, QR Codes store data both horizontally and vertically. This design provides significantly more data capacity and allows reading without specialized devices.

A QR Code typically appears as a square grid of black pixels on a white background. This pattern encodes alphanumeric data such as website URLs, contact info, or product details. You can scan them using the camera on a smartphone or mobile device, which eliminates the need for expensive proprietary scanners.

There are two main types of QR Codes:

- Static QR Codes: The information is hard-coded into the pattern. You cannot change the data once you create the code.

- Dynamic QR Codes: The code points to a short URL that redirects to the final destination. You can update the destination anytime without reprinting the code. This flexibility is crucial for codes used in marketing and inventory tracking.

How do QR Codes work?

QR Codes work through visual contrast. A smartphone camera or other scanner captures the image of the code. Software then analyzes the positioning of the three large squares in the corners (position markers) to orient the image. The device decodes the pattern of pixels to extract the information.

Modern QR Codes include built-in error correction. This means the code remains scannable even if it sustains damage or becomes partially covered by dirt. This durability makes them reliable for inventory management and industrial environments.

QR Code use cases

QR Codes are incredibly versatile because anyone with a phone can scan them.

- Marketing and customer engagement: Brands use them on packaging to link to video tutorials, social media pages, or loyalty programs.

- Inventory and operations: Warehouses use them for inventory tracking because staff can scan items with tablets or phones rather than sharing expensive RFID readers.

- Payments: Retailers and restaurants use them for contactless payments and digital menus.

- Information delivery: Museums and tourist sites use them to provide instant access to guides and maps.

RFID tags vs QR Codes: Key differences

Comparing RFID tags and QR Codes helps you understand which tool offers the best functionality for your goals. RFID systems offer speed and bulk scanning but come with high costs. QR Codes offer flexibility and low barriers to entry.

Here is a direct comparison of how they stack up:

| Feature | RFID Tags | QR Codes |

| Line of Sight | Not required. Reads via radio waves. | Required. The scanner must see the code. |

| Equipment | Requires specialized RFID readers and antennas. | Works with any smartphone or mobile device. |

| Cost | High. Tags range from cents to dollars; readers cost thousands. | Low. QR Codes are free or low-cost to generate. |

| Scan Speed | High. Can scan hundreds of items at once. | Moderate. Scans one code at a time. |

| Data Capacity | High. Can store complex data on the microchip. | High. Can store extensive alphanumeric data or link to any URL. |

| Durability | Vulnerable to magnets, metals, and liquids. | High error correction handles damage well. |

| Setup | Complex. Requires hardware installation and software integration. | Simple. Generate, print, and stick. |

Why QR Codes are better for most use cases

While RFID technology has its place in large-scale logistics, QR Codes often provide a smarter, more adaptable solution for most businesses. They offer a unique blend of scalability and ease of use that expensive hardware cannot match.

No limit to scan distance

People often claim RFID wins on range, but that is only true for expensive active RFID tags. Passive tags often have a range of just a few meters.

QR Codes scan from any distance where the camera can resolve the image. You can scan a small code on a product box from inches away. You can also scan a massive code on a billboard from hundreds of feet away. The range depends on the size of the code and the quality of the camera rather than the strength of a radio signal. This visual nature eliminates issues with signal interference from metal shelving or liquid containers.

Durability and error resistance

RFID tags contain delicate electronics. A strong magnet, a static shock, or physical crushing can destroy the microchip or detach the antenna. Once the internal circuit breaks, the tag is dead.

QR Codes are images. They rely on high levels of error correction. A QR Code can often still function even if 30% of the image suffers damage. You can print them on weather-resistant materials or etch them directly onto metal assets for permanent durability. This resilience makes QR Code inventory management ideal for tracking tools on construction sites or assets in outdoor storage.

Customization for branding

RFID tags usually look like plain stickers or plastic fobs. They offer zero visual value to the customer.

Once you understand how QR Codes are generated, you’ll see that they enable robust branding. You can customize the colors, pattern, and frame to match your company identity. You can even place your logo in the center of the code. This turns a functional tracking tool into a marketing asset. A branded code on product packaging encourages customers to scan for product information, warranty registration, or reorders. It builds brand awareness while serving a functional purpose.

RFID systems also require all users to buy and maintain specific hardware. If a fixed reader breaks or a handheld scanner battery dies anywhere along the chain, your operation stalls.

QR Codes democratize the scanning process. Every employee and customer already carries a scanner in their pocket: their smartphone.

This setup allows you to scale your asset tracking or inventory management system immediately without purchasing new equipment, and even extend supply chain functionality out into the marketplace by updating the Dynamic QR Codes on batches that have shipped so they now point directly to end-user resources. You simply print a QR Code for logistics, and your team can start scanning internally and sharing your branded landing sites externally with a single tech. This “Bring Your Own Device” (BYOD) capability reduces technical barriers and training time internally and across your customer base.

Flexible marketing applications

RFID is invisible to the consumer. They cannot interact with it. QR Codes invite interaction.

You can use QR Codes across every channel. Place them on direct mailers to track conversion rates. Add them to social media posts to drive app downloads. Print them on store signage to offer contactless checkout.

They bridge the gap between offline assets and online content in a way that creates a unified customer experience. Dynamic QR Codes allow you to change the destination URL based on factors like ship date, season, or campaign goals. This flexibility allows one code to serve multiple purposes over its lifespan.

Editing and tracking

Updating an RFID tag often requires rewriting the data on the chip using a specialized writer. This takes time and proximity.

Dynamic QR Codes offer superior management capabilities. You can update the information the code points to instantly through a dashboard. You do not need to be near the physical code to change its function. If you print a code on 10,000 brochures and realize the link is wrong, you simply update the destination URL in your generator. No reprint is necessary.

Furthermore, these codes provide rich analytics. You can track exactly when, where, and which device scanned your code. This real-time tracking data helps you optimize your campaigns and operations.

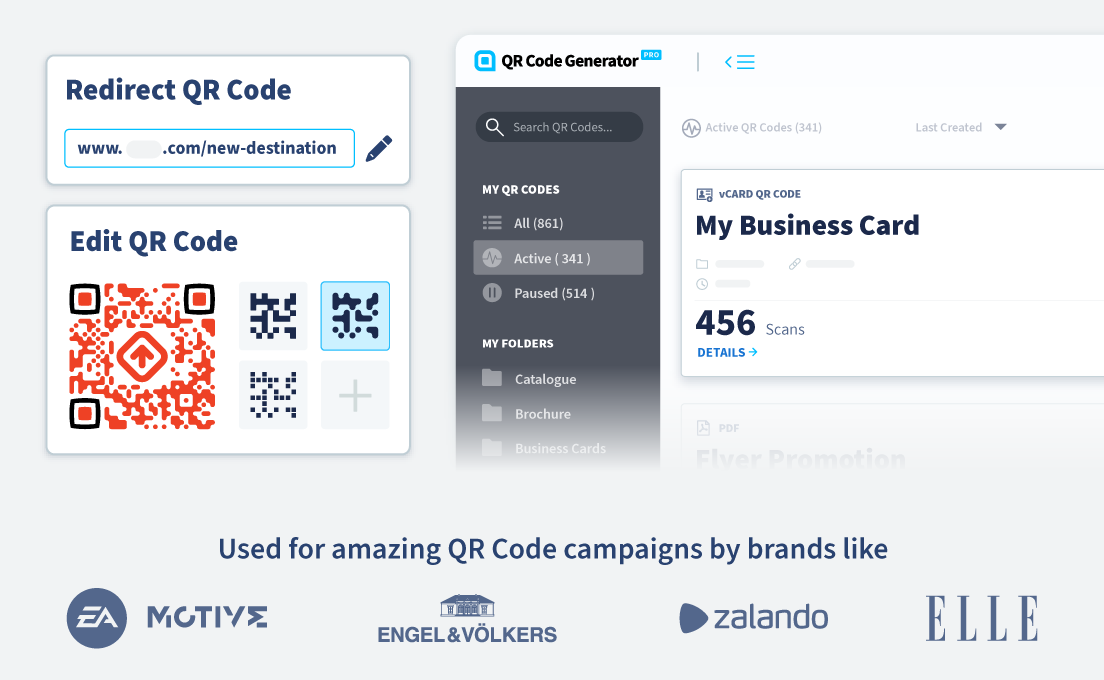

Start using QR Codes today with QR Code Generator PRO

Choosing between RFID tags and QR Codes comes down to accessibility and ROI. RFID requires a heavy upfront investment in infrastructure. QR Codes offer a flexible, low-cost alternative that leverages the devices you and everyone in your product chain already own.

For most businesses looking to streamline operations, improve inventory control, or boost marketing engagement, the choice is clear. QR Codes provide the versatility to track assets in the warehouse and engage customers in the store.

QR Code Generator PRO empowers you to create custom, trackable codes that grow with your business. You get the security, scalability, and design tools you need to succeed.

Ready to modernize your tracking? Log in to QR Code Generator PRO and start creating the best codes for your business today.

Add custom colors, logos and frames.

Add custom colors, logos and frames.