- Best Practices ●

- COVID-19 ●

- Industry Trends ●

- Partners ●

- Product ●

QR Codes for Maintenance Logs: A Smarter Manufacturing Fix

Unplanned equipment downtime can disrupt entire production lines and rapidly increase costs. By using QR Codes, maintenance teams can get instant access to maintenance logs, asset information, repair manuals, and compliance records right from a smartphone or mobile device. This real-time access helps streamline maintenance operations, improve preventive maintenance, and reduce human error across the facility.

In this article, we’ll explore how QR Codes simplify maintenance processes, automate recordkeeping, and boost operational efficiency for every team member. With Bitly’s trackable, SOC-2 compliant Dynamic QR Codes, manufacturers can modernize their CMMS, or computerized maintenance management system, software and turn maintenance workflows into a connected, data-driven advantage.

Note: The brands and examples discussed below were found during our online research for this article.

-

Table of contents

- How do QR Codes improve maintenance logs?

- Why QR Codes are useful for reducing downtime overall

- Key use cases for QR Codes in maintenance

- Asset tagging and tracking

- Preventive maintenance checklists

- Troubleshooting and repair guidance

- Compliance and audits

- Inventory and spare parts management

- What to consider when implementing QR Codes in maintenance logs

- Use Dynamic QR Codes for flexibility

- Place codes in accessible, durable locations

- Add clear CTAs

- Regularly review and update QR-linked data

- Train employees on scanning and logging

- Addressing challenges and misconceptions

- QR Codes aren’t durable enough

- Security concerns

- Integration with legacy systems

- How Bitly supports enterprise-ready QR Code maintenance systems

- Build resilient maintenance strategies with QR Codes

How do QR Codes improve maintenance logs?

Unplanned equipment downtime is one of the greatest cost drivers in manufacturing. Research pegs the average cost of downtime at $250,000–$260,000 per hour in many industrial settings. Even a short stoppage of 10 minutes can translate into lost output, labor idling, shortened production windows, and ripple effects across supply chains. When downtime lasts, the financial impact balloons due to opportunity cost, scrap, overtime, and cascading delays.

One silent but pervasive contributor to extended downtime is poor recordkeeping. When maintenance logs, repair histories, manuals, or compliance data are missing, incomplete, or wrong, teams waste time hunting for information, redoing work, or making unwise decisions. That delay eats at response times and raises the odds of human error.

On the compliance side, industrial facilities often face inspections, audits, safety regulations, or environmental mandates. If staff fail to document equipment certification records, inspection logs, or maintenance schedules properly, the plant is vulnerable to fines, forced shutdowns, and even legal liability.

Worse, paper logs and spreadsheets are prone to transcription errors, losses, or version control issues. These legacy approaches leave gaps that can cripple maintenance operations at critical times.

With a QR-enabled system, you’re essentially bridging each physical asset to its digital twin: Its maintenance history, repair logs, compliance files, manuals, and more. A technician using a smartphone or tablet can scan a unique QR Code and immediately gain instant access to maintenance operations data and workflows. No more rummaging through stacks of binder volumes or opening multiple spreadsheets.

Because QR Codes are more flexible than barcodes, in that they can be dynamic (redirectable) and hold metadata, they represent a clear evolution beyond static tags or numbered Excel files. They’re a centralized gateway from the physical world (the machine) to the digital domain (your CMMS, logs, and histories).

Why QR Codes are useful for reducing downtime overall

Reducing downtime starts with fast access to the right information. QR Codes give maintenance teams instant access to repair logs, maintenance records, and troubleshooting guides. When every asset has a unique QR Code, technicians can scan to view its full maintenance history, including past repairs, spare parts, and notes, improving response times and preventing production losses.

They also enhance preventive maintenance by linking to checklists, maintenance schedules, and service reminders. Following standardized steps in a CMMS mobile app helps identify potential failures early and keep assets running efficiently.

By digitizing access to maintenance logs, QR Codes can reduce human error, assist in accurate data entry, and create a verifiable trail for audits and warranties. Integrated with CMMS software, Dynamic QR Codes enable real-time data sharing so every team member sees current updates, keeping workflows connected, compliant, and optimized to minimize downtime and boost operational efficiency.

Key use cases for QR Codes in maintenance

By linking physical equipment to its digital profile, QR Codes simplify data entry, improve maintenance processes, and give technicians instant access to the information they need, all from a device they already own. Let’s examine several high-impact use cases that demonstrate how using QR Codes transforms maintenance operations to minimize downtime.

Asset tagging and tracking

Assigning unique QR Codes to each machine or tool provides quick access to critical asset information such as repair histories, maintenance records, and warranty data. Scanning a code instantly displays the asset’s history, helping technicians diagnose issues, record updates, and streamline maintenance workflows across your facility.

Preventive maintenance checklists

QR Codes for quality assurance simplify preventive maintenance by linking directly to service checklists, manufacturer guidelines, and maintenance schedules. This integration ensures every team member follows consistent steps, reducing the risk of human error and unplanned breakdowns.

Troubleshooting and repair guidance

QR Codes can connect technicians to manuals, schematics, and video tutorials for faster, more accurate repairs. Whether through a CMMS mobile app or a cloud-based maintenance log, this approach saves steps, improves response times, and makes onboarding easier for new technicians who need clear, reliable repair guidance.

Compliance and audits

When you digitize every inspection, repair, and work order, QR Codes can help your team create timestamped maintenance logs that simplify compliance verification and warranty management. Auditors can scan a code and see the full service record, making reviews smoother, in much the same way QR Codes for housekeeping requests help brand auditors at major hotel chains ensure cleaning and refurbishing standards are being met.

Inventory and spare parts management

Codes placed on shelves or bins can link directly to a QR Code storage system, helping teams track spare parts inventory levels, reorder items automatically, and prevent stockouts. This integration supports your CMMS by keeping real-time data synchronized between maintenance operations and supply chain activities.

What to consider when implementing QR Codes in maintenance logs

Implementing QR Codes across your maintenance operations requires more than just printing and sticking labels. You should follow a few best practices that keep QR-enabled systems accurate, durable, and effective.

Use Dynamic QR Codes for flexibility

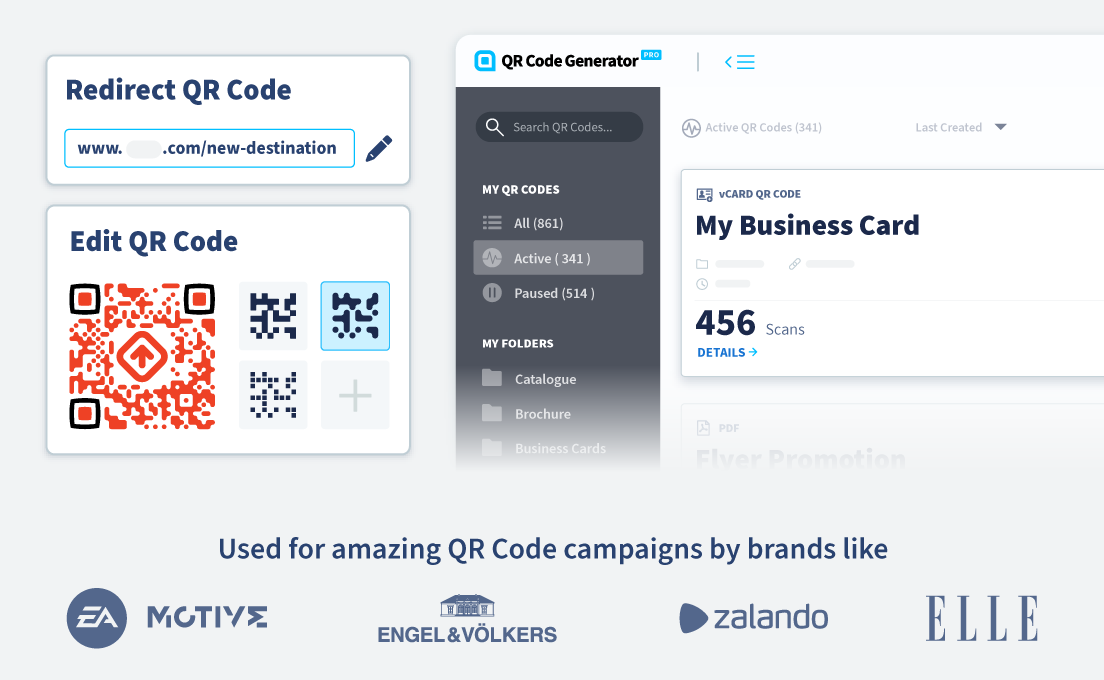

Dynamic QR Codes allow you to update linked URLs or files without reprinting physical codes. This flexibility is essential when teams need to adjust maintenance logs, checklists, or asset information as equipment changes. These codes also enable QR Code scanning analytics, so you can track usage metrics and identify bottlenecks in your maintenance processes.

Place codes in accessible, durable locations

Mount each QR Code where technicians can reach it during high-traffic operations. For harsh environments, use industrial-grade stickers, metal plates, or etched tags that resist oil, moisture, and heat.

Add clear CTAs

Every QR Code should tell technicians exactly what it does. A custom frame with short, visible instructions like “Scan for maintenance history” or “Access checklists” helps rotating team members identify the right code quickly.

Regularly review and update QR-linked data

Your CMMS relies on current, accurate data. Schedule regular reviews to confirm that all linked manuals, maintenance records, and work orders reflect your latest updates. Outdated links can delay response times or cause staff to miss preventive maintenance.

Train employees on scanning and logging

A successful rollout of QR Codes for quality assurance depends on training. Make sure every technician understands how to scan QR Codes, log updates through your CMMS software or mobile app, and sync their entries with the main maintenance history database.

Addressing challenges and misconceptions

Despite the clear benefits, some teams hesitate to adopt QR Codes in their maintenance operations. Common concerns include:

QR Codes aren’t durable enough

In manufacturing environments, QR Codes face heat, moisture, and heavy wear. Fortunately, industrial-grade labeling methods solve this problem. Laminated labels resist oil and abrasion, stainless-steel or aluminum plates withstand vibration and corrosion, and thermal transfer printing ensures visibility even under extreme conditions. The right materials give maintenance teams reliable QR Code scanning performance for years, ensuring consistent upkeep and quick asset tracking in harsh environments.

Security concerns

Some organizations worry that using QR Codes opens data to unauthorized access. However, enterprise-grade solutions like Bitly provide SOC-2 compliant, secure QR Code management. You can segment control over code creation by role and monitor activity through verbose audit trails. Dynamic QR Codes add another layer of control, allowing updates, redirects, or deactivations by authorized administrators in real time, all while protecting sensitive assets.

Integration with legacy systems

Another misconception is that QR Codes can’t integrate with existing CMMS or ERP software. QR Codes actually complement these tools perfectly. They link physical assets to digital maintenance records, giving technicians on-demand access while keeping the master data centralized. Whether for data entry, preventive maintenance, or spare parts management, QR Codes enhance legacy systems rather than replace them.

Far from being “basic” or “unreliable,” QR Codes now serve as a scalable bridge between manual workflows and digital ecosystems, helping facilities keep every team member aligned across the entire maintenance lifecycle.

How Bitly supports enterprise-ready QR Code maintenance systems

Bitly helps manufacturers modernize their maintenance operations with secure, scalable QR Code solutions built for enterprise use. Dynamic QR Codes let teams update destinations, link to new files, or adjust workflows without reprinting. Each scan delivers real-time data on usage, location (city/country), and device type, helping leaders track performance, improve response times, and reduce downtime.

For organizations prioritizing data security, Bitly’s platform is SOC-2 compliant, meeting the highest standards for confidentiality and governance. QR Codes created by Bitly integrate seamlessly, connecting maintenance logs, checklists, and compliance records across the entire operation.

Whether managing one facility or hundreds, Bitly gives enterprises the flexibility and visibility to scale. By uniting maintenance team tracking, asset oversight, and analytics in one secure system, Bitly positions QR Codes as more than labels. They become powerful tools for improving operational efficiency, reducing human error, and streamlining enterprise-wide workflows.

Build resilient maintenance strategies with QR Codes

Unplanned downtime can cost you thousands per minute, but QR Codes help prevent it by making maintenance logs more accessible, accurate, and secure. By connecting each asset to its digital record, teams gain instant access to maintenance history, work orders, and checklists, directly from a smartphone or mobile device.

QR Codes also enable better preventive maintenance, help ensure compliance, and give technicians the tools to act on reliable, real-time data. With Bitly’s enterprise-grade, SOC-2 compliant Dynamic QR Codes, you can scale securely across facilities, link to CMMS software, and eliminate human error from manual data entry.

Ready to streamline your maintenance operations and reduce downtime? Log in today to explore our secure, scalable QR Code solutions.

Add custom colors, logos and frames.

Add custom colors, logos and frames.