- Best Practices ●

- COVID-19 ●

- Industry Trends ●

- Partners ●

- Product ●

How to Use QR Codes for Maintenance History

Many teams end up burying maintenance logs in spreadsheets, binders, or siloed software systems, leaving technicians searching for critical details when they need them most. QR Codes solve that problem by giving maintenance teams instant access to accurate, real-time asset information with a single scan from a smartphone. Whether you’re checking a piece of equipment’s service history or updating a work order, QR Codes simplify the process and reduce human error.

In this guide, you’ll learn how to use QR Codes to track and update maintenance history, streamline maintenance workflows, and keep equipment performing at its best. You’ll also see how to use QR Code maintenance logs to reduce downtime by improving safety, reliability, and cost efficiency across your facility.

Note: The brands and examples discussed below were found during our online research for this article.

-

Table of contents

- Why QR Codes simplify maintenance tracking

- Common challenges with traditional maintenance logs

- How Dynamic QR Codes make tracking easier

- Provide easy access to a CMMS with QR Codes

- Access and update other maintenance records with QR Codes

- How to create QR Codes for maintenance management

- Step 1: Choose what your QR Code should link to

- Step 2: Create your QR Code with QRCG

- Step 3: Customize and test

- Step 4: Apply and maintain visibility

- Best practices for using maintenance QR Codes

- Use Dynamic QR Codes for long-term tracking

- Add clear CTAs for technicians

- Perform regular QR Code upkeep

- Organize Codes in folders for easy management

- Real-world examples of QR Codes for maintenance history

- Manufacturing

- Property management

- Facilities maintenance

- Public sector

- Simplify maintenance management with QRCG’s QR Codes

Why QR Codes simplify maintenance tracking

QR Codes help transform maintenance tracking from a time-consuming chore into a seamless process. By scanning a code on a specific asset, technicians gain instant access to digital records like service logs, safety procedures, and inspection checklists. This real-time access eliminates guesswork and ensures every maintenance task uses the most accurate, up-to-date information. With QR Codes, teams can view and update an asset’s history directly from a smartphone’s browser or a mobile app, streamlining data entry, preventing delays, and reducing opportunities for human error.

Having essential asset information available on mobile devices they already own keeps maintenance teams efficient and responsive. They can review maintenance schedules, complete work orders, or log inspections on the spot, minimizing distraction and keeping every piece of equipment performing reliably.

Common challenges with traditional maintenance logs

Traditional maintenance logs often create more problems than they solve. People misplace paper records, spreadsheets become outdated, and nested network folders can make it hard to find the right file. These inefficiencies can lead to missed preventive maintenance, duplicated tasks, and longer repair times.

QR Codes eliminate these issues by linking directly to the latest version of a maintenance record. A single scan connects technicians to real-time data, whether they’re tracking a service history, verifying warranty details, or reviewing previous maintenance activities.

How Dynamic QR Codes make tracking easier

Do QR Codes expire? Only if you remove the item they’re pointing at. However, Dynamic QR Codes take maintenance tracking a step further. Unlike static codes, which can’t change once printed, you can update the destination URLs of Dynamic QR Codes at any time, making them ideal for rotating assets, recurring maintenance tasks, or shared equipment. Technicians can scan the same code to view the most current work orders or inspection checklists without replacing or reprinting anything.

Dynamic QR Codes also record valuable scan analytics, including date, device, and use frequency. This data helps confirm that staff complete inspections and maintenance activities as scheduled, providing accurate records without manual logging. The result is a more accountable, automated, and efficient maintenance process.

Provide easy access to a CMMS with QR Codes

A manufacturers can modernize their CMMS, or computerized maintenance management system, software helps facilities track work orders, labor hours, and maintenance costs. However, finding the right record can still be a challenge. Navigating through lists of assets or searching by ID numbers often slows technicians down, especially when time matters most. QR Codes solve this by acting as quick entry points into specific CMMS records, giving maintenance teams instant access to critical data with a single scan.

For example, scanning a QR Code on a generator can open its full maintenance history, inspection schedule, and spare parts inventory in seconds. Technicians can update work orders, log repairs, or mark completed maintenance tasks directly from a mobile device. This setup saves time, reduces human error, and ensures the latest information is always available in real time.

Even for facilities that still rely on spreadsheets or simpler tracking systems, QR Codes provide mobile-friendly access to essential data. By linking each asset’s QR Code to its record, teams can streamline updates, view detailed information on site, and maintain a reliable maintenance history without investing in new software. This approach keeps maintenance processes fast, accurate, and accessible for every technician in the field.

Access and update other maintenance records with QR Codes

QR Codes make it simple to connect technicians directly to the maintenance records they need. Each code can link to a digital log, shared drive, or spreadsheet containing up-to-date data about a specific asset. With one quick scan, maintenance teams can review repair notes, add new service entries, or attach inspection photos, keeping every maintenance record current and easy to find.

In professional settings like manufacturing plants or property management, QR Codes can track maintenance activities across multiple locations. Scanning a code on a conveyor system might display its lubrication log or replacement parts list, while a code on an HVAC unit could open its service history and warranty details. Even for home or small business use, QR Codes simplify tracking appliance repairs or annual inspections without stacks of paper or scattered files.

Dynamic QR Codes make updating easy. When linked documents or asset information change, you can simply update the destination instead of reprinting labels. This flexibility saves time and ensures every technician always accesses the most accurate maintenance data.

Over time, these connected maintenance workflows help ensure warranty compliance, reduce unnecessary costs, and strengthen preventive maintenance programs. With every scan, teams gain quick, reliable insight into each asset’s history and performance, making long-term upkeep more efficient and less time-consuming.

How to create QR Codes for maintenance management

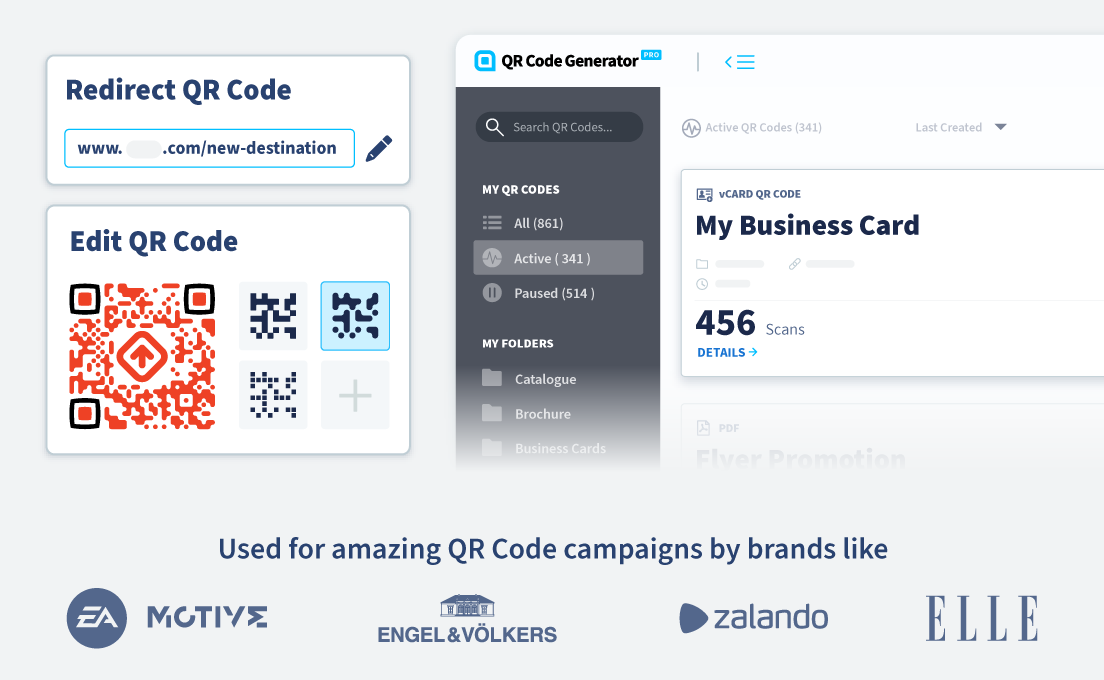

Creating QR Codes for maintenance tracking is quick and easy, especially when you follow a clear workflow. Whether you’re managing a CMMS or tracking assets with spreadsheets, QR Codes connect your team to essential maintenance data in seconds. Here’s how to set them up efficiently with QR Code Generator PRO:

Step 1: Choose what your QR Code should link to

Start by deciding which type of maintenance record your QR Code will connect to. You might link it to a digital maintenance log, a parts inventory sheet, a work order form, or a safety checklist. Or even a summary microsite with links to all these resources. Each scan gives technicians instant access to specific asset details and reduces time spent searching through files.

Step 2: Create your QR Code with QRCG

Next, sign up for your QRCG account and select CREATE QR CODE from your dashboard. Choose a content type like Website, PDF, or Video, depending on what you want to share. Within seconds, you can generate a unique QR Code that links directly to your selected document or page. For clarity, include a short call to action such as “Scan for Maintenance History” or “Scan for Work Order.”

Step 3: Customize and test

QRCG makes it simple to personalize each QR Code. Add distinct colors, patterns, or small icons to tell Codes apart, which is helpful when multiple Codes appear on one piece of equipment. Before printing, test every QR Code using multiple devices and mobile apps to ensure it scans quickly and accurately.

Step 4: Apply and maintain visibility

Place your QR Codes where they’re easy to find and scan, such as on control panels, service tags, or nearby signage. For harsh or high-traffic environments, consider using laminated stickers or durable metal tags. Keeping QR Codes visible and protected helps maintenance teams access real-time information anytime, reducing downtime and improving overall equipment maintenance efficiency.

Best practices for using maintenance QR Codes

Using QR Codes for maintenance tracking works best when you design and manage codes with clarity. A few smart habits can keep your maintenance processes efficient, organized, and easy to scale across facilities.

Use Dynamic QR Codes for long-term tracking

Dynamic QR Codes are the most flexible option for maintenance management. Unlike Static QR Codes, they let you update the destination URL anytime without reprinting labels. This saves time and reduces waste, especially when assets move between departments or inspection requirements change. For example, a Dynamic QR Code on an air compressor can first link to a startup checklist and later connect to its maintenance history or warranty record, all using the same label.

Add clear CTAs for technicians

Every QR Code should clearly communicate its purpose. Adding a simple call to action like “Scan for Maintenance Log” or “Scan for Service History” helps rotating technicians or new staff understand what they’ll access. Color-coding or using QR Code Generator’s built-in call-to-action frames can make these codes stand out on busy equipment panels, improving adoption and reducing confusion.

Perform regular QR Code upkeep

Even the best maintenance QR Codes need a little maintenance of their own. Check labels periodically to make sure they’re still legible and scannable. Replace damaged or faded codes as needed, especially on outdoor or high-use equipment. QR Code Generator PRO’s high error correction ensures codes remain functional even if slightly worn, keeping your team’s workflows uninterrupted.

Organize Codes in folders for easy management

As your asset library grows, keeping everything organized becomes critical. Use QR Code Generator PRO’s folder system to group QR Codes by asset type, department, or location. For example, facility management teams can store all HVAC, electrical, and plumbing codes in separate folders for instant access. This structure streamlines asset tracking and makes it easy to locate, update, or reprint codes when needed.

Real-world examples of QR Codes for maintenance history

QR Codes are transforming how maintenance teams across industries manage and access critical data. By linking physical assets to digital maintenance records, organizations of all types can improve accountability, reduce downtime, and streamline inspections. Here are some practical examples of how different sectors are using QR Codes for maintenance tracking.

Manufacturing

Production facilities often place QR Codes for manufacturing directly on machines to link service logs, inspection checklists, and compliance documentation. A technician can scan a code on a conveyor motor to view its maintenance history, record performance data, or confirm when preventive maintenance was last completed. This real-time visibility improves equipment performance and minimizes costly breakdowns.

Property management

Apartment complexes and office buildings use QR Codes to manage systems like HVAC units, elevators, and boilers. Scanning a code brings up maintenance schedules, recent repairs, and warranty details, giving technicians instant access to each asset’s history. For building managers, this approach simplifies reporting, improves tenant safety, and reduces missed maintenance tasks.

Facilities maintenance

QR Codes help facility management teams track everyday equipment such as lighting systems, pumps, and safety tools. When staff scan a QR Code, they can log inspections, update checklists, or attach images documenting repairs. This workflow ensures accurate maintenance records and faster follow-up when issues arise. There’s a reason many ISO-certified facilities choose to simplify quality control processes with QR Codes.

Public sector

Municipalities, schools, and public works departments use QR Codes to organize fleet vehicles, building systems, and public infrastructure. A scan on a utility truck’s code might show its maintenance records, service intervals, and assigned technician. By centralizing data in one place, public agencies improve accountability and extend asset life without increasing costs.

Simplify maintenance management with QRCG’s QR Codes

Managing maintenance data shouldn’t cause headaches. QR Code Generator PRO makes it easy to create, update, and organize QR Codes for every maintenance process, no technical setup required. With just a few clicks, you can generate Dynamic QR Codes that link directly to maintenance logs, inspection checklists, or work orders and edit them anytime without reprinting.

QRCG’s durable, customizable QR Codes withstand daily use, giving maintenance teams instant access to accurate, real-time information right from their mobile devices. The result is fewer errors, faster repairs, and smoother maintenance workflows across your facility.

Ready to simplify your maintenance management? Sign up for QR Code Generator PRO and start creating smarter, more connected maintenance systems today.

Add custom colors, logos and frames.

Add custom colors, logos and frames.